Translating Shuttle Foil Approach

The FACTS Behind the TechnologyFact: 71% of the world surface is ocean. All oceans have currents and some tidal flows. The energy within these flows is endless and tremendous. Given all this clean energy why are we still be forced to buy oil, coal, gas and nuclear power? How much more will you tolerate from your politicians on how fossil fuels and nuclear power are still needed? All the needed fuels and electricity can be produced cleanly / sustainably using TSF produced ultralow cost electricity!

TSF Clean Cheap Electricity Can Facilitate the Production of Synthetic Carbon-Neutral, Hydrocarbon Fuels Which Can Make Every Gas/Diesel, Natural Gas Vehicle or Appliance as Sustainable as Their Electric Power Version!

Below are links to all necessary downstream technologies which can produce carbon-neutral eFuels and eGas TODAY; These technologies also exist today but the fossil fuel industry DO NOT want you to know about them! Think of the money you would save if you only had to put sustainable eFuel in your car, or your home appliances — the savings to the average family would be into the 10s of thousands!

- https://www.bosch.com/stories/synthetic-fuels/

- https://www.sunfire.de/en/

- https://carbonengineering.com/

- https://www.climeworks.com/

- https://fuelcellsworks.com/news/fuel-of-the-future-technion-researchers-have-developed-an-inexpensive-environmentally-friendly-safe-hydrogen-technology/

- https://www.cnbc.com/2019/06/21/carbon-engineering-co2-capture-backed-by-bill-gates-oil-companies.html

- https://www.asme.org/topics-resources/content/sailing-above-below-water-generate-power

Translating Shuttle Foil Prototypes in Action

This video which shows just how simple the TSF approach can produce electricity. https://www.youtube.com/channel/UCqXgENZiu0ptsx3kN9jomPA

The picture below shows the underwater portion of the Floating Foil Array not visible in the video above. As the angel of attack of the shown vertically installed foil array is changed, the floating foil array reverses direction. The simple demonstration model can easily be scaled up to super tanker or aircraft carrier size with corresponding outputs.

Watch another video here>>

The picture below shows a Floating Foil Array static tinsel thrust/pull test at Northwest Hydraulic Consultants test facilities in North Vancouver, British Columbia, Canada in 2018.

Above, static tinsel pull test of the ‘Floating Foil Array’. Test parameters: Flow velocity: 0.38 meters per second, frontal harvest area: 0.4 square meters. Forces realized in this static test range from 18 lbs to 20 lbs. It is important to note that pulling forces would be higher if the Floating Foil Array were moving laterally across the flow. This is due to ‘apparent flow’ influences: the higher the translational velocity, the higher the power coefficient.

The ‘Floating Foil Array’ test rig in the empty water flume. The three foils can be seen set at the optimum ‘static harvest angle’ (AOA) of 45 degrees.

Real-world operational AOAs will be higher, thereby yielding higher tinsel pull / thrust outputs.

For more information on how scaled-model test results can can be converted and applied to larger versions, see https://en.wikipedia.org/wiki/Reynolds_number.

The TSF Approach is Based on Proven Fluid Dynamics:

Any naval architect, sail designer, even a well-seasoned sailor, will tell you that in a twelve meter per second wind, one square meter of sail area will produce the equivalent of 0.75 horsepower. That’s a lot of power when you consider that sails can be hundreds, even thousands of square meters in size.

Real world practical proof: the world’s largest sailboat, the Mirabella 5 (a.k.a. M5), has a combined sail area of 3,400 sq. meters. In a moderate wind, using only her sails, she can achieve considerably higher cruise speeds than via her combined 2,600 horsepower (two Megawatts) inboard diesel engines. That means that her sails can harvest considerably more energy than is produced by her large diesel engines. For a displacement hull vessel to achieve higher speeds under wind power than her design hull speed (to the maximum of which her engines are able to move her) significantly more energy / horsepower is required than is supplied by the engines.

Example of How Much Power Could be Created:

A TSF wind system, with a combined sail area of 25,000 sq. meters (deployed via multiple ‘sail’ or ‘foil’ sets) operating in a 12 m/s wind could theoretically produce the equivalent of roughly 18,750 horsepower! That’s almost 14 megawatts. A large, conventional wind turbine with a similar ‘swept area’ in a similar velocity wind will produce only about 5 MW. Are you getting the picture?

TSF ultralow cost driver comes from their much wider operating envelope in terms of being able to not only start producing electricity at lower flow velocities but also not having an upper flow velocity cut-out velocity this means much more total annual energy production than conventional wind turbines.

Hence, their total hours of operation/production per year are much longer than conventional approaches, hence, lower cost per kWh harvested.

The required infrastructure costs and direct operating costs of (any) TSF variant will also be much lower than any other convention energy production / harvesting means in use today, again, lower electricity cost – which is not only great for consumers and businesses but will also make the TSF process the key cost facilitator of all synthetic, carbon-neutral eFuels/eGas.

If a similar sail / foil area mentioned above were to be employed by a hydrokinetic TSF system in a fast flowing ocean current, like the Florida Current of the Japan Current or any number of ocean currents worldwide (some of which over 2 m/s per second and for many hundreds of square kilometres each — 24 hours per day!), or; into any number of tidal flows which cover thousands of sq. kilometres worldwide (some of which have much higher peak flow velocities than ocean current), each individual TSF hydrokinetic system could easily have outputs of into the hundreds’ of MW.

That would be a considerably higher output than for an entire conventional wind farm which employs many dozens of wind turbines – and for much longer periods of time per year! Fact: the average wind turbine wind farm will only operate at their placarded max output of 99 MW for about 30% of the time. Again, are you getting the picture?

How are such outputs possible?

Fact: salt water is 832 times denser than air, that means that an current current flowing at 1 meter per second, in which a medium sized hydrokinetic TSF farm (or ‘hive’ as we call it), is installed, will have far higher outputs (24/7/365) than not only any wind farm in the world but also even the largest dam in the world. And TSF Hives will actually be good the marine life as their vast foil areas (both sides) will create truly vast new artificial reef areas for marine life to thrive on! ‘Marine fowling’, as it know to boaters, is actually good for TSF systems as it aids in kinetic energy transference from the passing water to the foils via added friction!

Supporting Facts:

One cubic meter of water, flowing at (just) one meter per second (roughly slow walking speed) contains roughly 500 watts of potential energy, now consider the output of a large TSF hydrokinetic farm, which could (easily) make continuous contact with over a million cubic meters of flowing water per second, this is possible because a large TSF hydrokinetic farm can theoretically place well over a million square meters of foil area into the flow!

Remember that the world’s tides flow vast amounts of water four times a day, every day! Even more important, the world’s ocean currents have continuous extreme flow volumes 24 hours a day, every day.

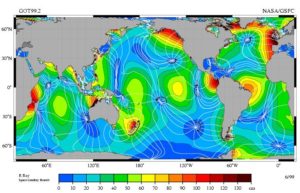

The red areas in the picture above shows the highest velocity tidal flows. It is also important to remember the kinetic energy formula: Kinetic Energy = 1/2 mass x velocity squared, meaning every time velocity doubles, kinetic energy quadruples.

The untapped energy in our oceans from ocean currents and tidal flows is not only extreme, it is inexhaustible, and is just waiting to be harvested and TSF hydrokinetic systems can harvest from our oceans in a 100% sustainable fashion.

Critical factors which support TSF viability and soonest possible use

- Fresh water weighs 800 times more than air by volume (saltwater: 832 times)

- Water has 50 times the viscosity of air

- One cubic meter of water, flowing at 1 m/s contains circa 500 watts of ‘potential energy’

- Billions of cubic meters of water flow 4 times every day worldwide via tide flows

- Billions more flow in ocean currents 24/7/365

- Rivers worldwide flow millions of cubic meters of water 24/7/365

- TSF Floating Foil Array variant can harvest from even shallow water (only needs 1 meter depth).

Portions of some tidal flows worldwide flow at over 5 m/s (mid tide peak flow). Some ocean currents flow at over 2 m/s – 24/7/365 – for hundreds of sq. kilometres.

TSF hydrokinetic variants make it possible to sustainably harvest from these extreme volume high velocity flows 24/7/365, hundreds, even thousands of kilometres offshore in international water and far away from consumer markets. By converting TSF produced electricity, into low cost hydrogen at the TSF operating sites TSF energy can be stored. By then directly converting the clean source hydrogen to ammonia (at very high energy density carrier) it can easily be shipped – by conventional tanker or barge – to any enduser market worldwide.

The ultralow cost of TSF kinetic energy harvesting and conversion makes the use of temporary energy storage processes viable – this a key kinetic energy harvesting facilitating factor.

Large TSF hydrokinetic systems will be able ‘suspend’ 10s of thousands of square meters of sail/foil/wing area into grade level flowing water – without the need to place any electrical component under the water; these are two extremely important TSF viability factors.

Hundreds of TSF hydrokinetic systems could be operated in ‘farm deployments’, in short separation sequence as the viscosity of water facilitates a relatively short distance for flows to re-stabilize (‘re-energize) themselves post upstream harvesting.

Tidal flows of all sized can also have many dozens of TSF systems installed in them, also in close succession.

Small to medium sized TSF wind or hydrokinetic system components can be centrally manufactured and shipped worldwide via standard shipping containers.

TSF Wind harvesting potential:

TSF wind systems can be installed hundreds of meters higher than convention HAWT ‘ground installed’ units hence, will have less or even no ground/surface friction to slow their wind stream, meaning the wind stream at higher altitudes will have higher velocity, meaning higher outputs for the same overhead installation locations as ground installed HAWT units below.

When installed across valleys, TSF wind systems will occupy no useable / arable valley floor lands

Valleys typically have bidirectional winds, making them ideal for TSF installations. There are literally endless valleys worldwide in which TSF wind (and or flowing water – river) TSF systems could be ‘co-installed’ in. Many ideal installation valleys already have both hillside and valley floor roads in place from previous commercial activity, thereby further reducing installation costs of both TSF wind and or FFA river systems.

The TSF systems are scalable: The TSF approach is scalable; from small military use, rapid deployable size, to extremely large, utility scale, 10s of MW each.

All TSF variants can be kept extremely simple and still allow them to have high outputs, making them ideal for use in developing countries.

Most TSF wind harvesting system components can be centrally manufactured and shipped via standard shipping containers.

Tidal flow / Ocean current harvesting potential via TSF systems:

The Pacific Northwest has one of if not the most accessible tidal flows in the world. British Columbia alone has a 27,000 km long (ice free) coast line, all of which has 4 tidal flows per day.

Along with the Bosch synthetic Green eFuels process, British Columbia could become one of the largest clean/sustainable energy producers/exporters in the world, and this, in less than 10 years.

Just like other tidal flows worldwide, the energy density of BC tidal flows are extreme and could easily provide all 60 plus million residents of western North America with all the electricity and sustainable Green eFuels they could ever hope to need and still have tremendous amounts left for export worldwide.

Eco-Friendly Aspects of all TSF Variants

All TSF variant ‘shuttle’ across the flow at very slow speeds, typically at less than half the velocity of the passing flow. Compare that to the blade tip speeds of a conventional wind turbine which can reach speeds of up to 300 Kph. Hence, TSF wind systems pose no potential threat to birds, bats, or humans, as TSF wind systems do not move fast enough to produce harmful, irritating ‘infra-sound’ (ultralow frequency sound). No component of any TSF variant can be weaponized such as could be the case with nuclear installations or fuels as was recently seen in Ukraine.

TSF hydrokinetic variants will have average translational velocities of about 1.5 to 2 meters per second. The potential for harm to even the largest marine mammals is virtually zero, certainly far lower than from commercial shipping traffic which typically travel at over 20kts (40 m/s).

Fact: The vast underwater ‘sail / foil’ areas that will be used by all Hydrokinetic TSF systems will be ‘perceived’ by marine life as vast ‘artificial reefs’. While boat owners which moor their boats call it ‘marine fowling’ e.g. barnacles, seaweed, etc., we call it ‘Nature’s helper’. Marine fowling on TSF sails is actually good for the kinetic energy transfer process from the passing water to the TSF sails as it slows the flow; this marine fowling assists in the kinetic energy transfer from the flow to the foil, causing the foil to be ‘dragged’ across the flow. Hence, TSF Hydrokinetic systems are in fact ‘drag devices’ versus the faster moving counterparts which are ‘lift producing devices’.

The large TSF underwater foils will be welcomed by marine life as they will quickly colonization them, and as that is exactly how marine ecosystems thrive – in fact, that is where the marine food chain starts. The more reefs the better, the more growth the better, the widespread use of TSF hydrokinetic energy harvesting systems in salt water means more marine life and food sources for both marine life and humans.

Given the vertical orientation of all TSF sails / foils, when the growth becomes too heavy, it simply falls to the ocean floor, which then becomes ‘food’ for ocean floor creatures.

Note: TSF hydrokinetic systems can be operate in any water depth; they do not need to be ‘ocean floor-mounted’ like other marine kinetic energy harvesting systems. For distant offshore operations, TSF systems can be strung between large barges and can be retained in place by anchor systems identical to how large drill platforms are retained now.

There are other inherent beneficial aspects to hydrokinetic TSF systems; for an example, all TSF hydrokinetic variants can harvest from ‘grade-level’ flows, meaning the building of dams and flooding of large areas of usable / arable lands is no longer necessary to produce electricity.

Fact: more energy can be had / harvested from flowing water, than can be if water is ‘dammed’ / stored in a giant reservoir and only harvesting from once (as the water flows through the turbines), and is then ‘discarded’ down river; the discarded (flowing water) ‘re-energizes itself’ in relatively short distances due to the river’s down-grade slope and the earth’s gravity. The moon’s gravity provides endless tidal flow power and the earth’s rotation induces ocean current flows. All of the above are ever-present / never ending energy sources which can be repeatedly be harvested from.

TSF Ground Footprint:

All TSF hydrokinetic systems will have extremely small usable land ground footprints (zero, for ocean current TSF systems). Meaning TSF systems will not require the flooding of large areas of otherwise arable land. If necessary for landlocked countries, TSF hydrokinetic ‘river’ installations will have very small shoreline footprints and also be highly cost effective alternatives for countries which simply can’t afford or have the necessary topography for conventional dams.

Think of the many rivers worldwide which do not have the ability to be (repeatedly) dammed, like the Amazon, the Nile, the Yangtze, Ganges, Mississippi, Missouri and so on, yet all can (literally) have hundreds, even thousands of smaller TSF hydrokinetic systems installed along their river banks (so as not to impede main river channel navigation).

The Proof: the 500 year-old ‘reaction ferry’ approach is a perfect and long in use working example of a simple TSF ‘Floating Foil Array’. Today, worldwide, ‘reactions ferries’, operate on some of busiest shipping rivers in the world, such as the Rhine (at Basil, Switzerland) and more.

Lytton, British Columbia, Canada has had a working reaction ferry for over 135 years and the operating conditions there are truly extreme with water level changes of many meters with the seasons (!) not to mention ice flows in the winter months. To see the Lytton reaction ferry in operation, cut and paste this link: https://www.youtube.com/watch?reload=9&v=IbsZXOF4Smk

Countries like Brazil could easily and quickly become one of the world’s largest exporters of clean source hydrogen and or carbon-neutral synthetic eFuels using TSF ‘shallow water’ river installations. The Amazon is 6,500 km long, it flows 209,000 cubic meters per second, the harvest-able clean kinetic energy contained in the Amazon River is simply tremendous, and harvest operations could easily be carried out there with very little impact on the immediate shoreline areas and in a completely sustainable fashion – forever!

TSF will Bring Tremendous Cost Savings to Consumers and Businesses

With a growing list of countries and cities planning to ban internal combustion engines vehicles in the very near future (14 countries and 25 major cities worldwide so far and growing) consumers and businesses living / operating there, will be forced to replace their perfectly functional (current) fossil fuelled vehicles (and natural gas appliances), with electric powered replacements, and this at significant cost to the consumer. With the advent of the TSF / carbon neutral synthetic eFuels technology combination, shedding internal combustion engine vehicles is no longer necessary. TSF produced clean electricity will make synthetic carbon-neutral eFuels / eGas production be highly cost competitive with all fossil fuels. In fact, at some point, synthetic eFuels will be half the cost so fossil fuels. The need to ban internal combustion engine vehicles is not only over, it was never a practical or even possible solution in the first place, as there simply isn’t enough wealth in the world to transition world mobility to an all electric world vehicle fleet in time to prevent runaway climate change. Why would any consumer throw away a perfectly good (paid for) car / truck / boat / plane / appliances, etc., when all they need to make them sustainable, is to operate them on synthetic, carbon-neutral eFuels or eGas?

Then of course there are the tremendous saving to consumers from the ultralow cost electricity that ALL TSF systems will produce as well. That is self-evident.

Then there are the savings to consumers of NOT having to pay for the increased costs of products / services which businesses would have to charge to cover their increased operating costs of having to upgrade their vehicle fleets / appliances to new electric units, etc. There will also be a huge savings to consumers, especially to all those who fly regularly, as electric or hydrogen-powered airliners are simply not practical or even possible (yet) but if airlines would be forced to buy them, you the air traveler will have to pay for the cost of replacing these perfectly good liquid fuelled airliners – when all that is needed is to have these current airliners use carbon-neutral jet fuels, you know, like the U.S. Navy is already doing as you read this.

The combined cost savings to businesses large and small, of TSF produced energy will easily be into the many trillions of dollars; just consider their (much) lower energy bills, or their ability to continue using their existing vehicle fleets / appliances. Now understand that there are well over a 1.4 billion vehicles and at least one billion natural gas appliances in use today worldwide. Then consider the rising costs to consumers of already happening climate change in the form of home / business insurance and damage repair / rebuilding costs which insurance companies will no longer cover – and so on.

There are also significant cost savings to consumers of suppliers NOT having to replace any portion of their existing (fossil) fuel distribution / refuelling infrastructure; remember, carbon-neutral eFuels are ‘chemically identical’ to fossil fuels, therefore they are 100% ‘blend-able’ with all fossil fuels; their distribution and use will NOT require any modifications to any component of the fuel supply chain, vehicles which use them or the gas stations which will sell them.

The Immediate Climate Change Reduction Benefits of Using Synthetic Carbon-Neutral eFuels / eGas:

For every litre of synthetic, carbon-neutral eFuel (or cubic meter of eGas) consumers will choose to fill-up with / use, there will NOT be the same amount of fossil-based gasoline, diesel, jet fuel, fossil-based natural gas extracted from the ground and refined. The produced carbon emissions of NOT extracting refining fossil fuels will save far more carbon emissions than what you burn in your car or natural gas appliance.

Today, about the equal amount of fossil-sourced power is used to produce a barrel of fossil fuel which eventually ends up in your vehicle’s tank – so by not using a litre / gallon of fossil-based gasoline, another litre/gallon of fossil based energy is NOT burned to produce the litre/gallon you use in your vehicle. This means two litres/gallons of fossil carbon does not end up in the atmosphere when synthetic carbon-neutral hydrocarbon eFuels are used.

Questions? Please ask! We look forward to sharing our ideas and knowledge with the world.